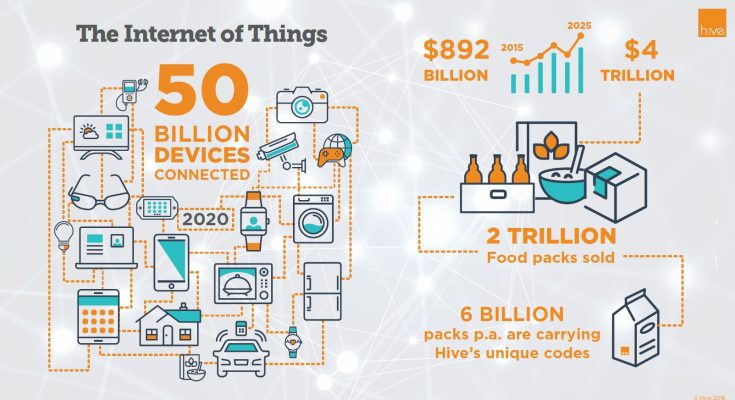

The Internet of Things is set to become a whole lot bigger as brand owners wake up to the possibilities offered by connected packaging, explains Jonathan Jackson of Hive

With major brands already exploring various ways of linking up their packs to the Internet, estimates that there will be 50 billion devices connected by 2020 are likely to be way under the true figure. There are nearly two trillion packs manufactured around the world every year; even if we assume that only 1% of them are connected to the IoT, then we are talking about 20 billion packs in the network.

Growth in connected packs has in the past been hampered by the cost involved in putting RFID or NFC chips on or in boxes; but that’s no longer a restriction, with the development of technology that allows brand owners to print unique codes on every individual item that comes off the production line at minimal unit costs.

Hive’s patented codes, for example, have been used on products such as savoury snack products, wine bottles and spreads, as well as on newspapers, magazines and samples.

Printing some kind of unique ID on pack is a cost effective, flexible and simple route for brands to leverage the power of packaging as a fundamental element of the customer journey.

Activating them is easy for consumers, too – alphanumeric ID codes are device-agnostic and there is no need to download apps, scan receipts, or email pictures of packs to the company, which have all proved to be barriers to truly marrying up physical packaging and the digital world in the past.

Unique codes cut straight through the complexity – it’s easy for consumers to find them on a pack or product and text them in or visit a promotional site and input them.

Research by one top 10 global manufacturer has shown that when a unique code is used for a promotion, it will drive an 8% increase in sales compared with the same promotion without a code.

And when a global drinks manufacturer ran an instant win promotion without a discount but with a unique identifier, it generated the same sales uplift as in the same period a year earlier, when the promotion included a 25% discount but no unique code. That means the second promotion was delivered at a fraction of the cost of the first and with a significantly better Return On Investment (ROI).

Unique codes and IDs are not exclusive to FMCG products, of course; they can be used in just about any industry (pharmaceuticals, luxury goods, white goods, cars, even B2B products). They are particularly attractive to marketers who are selling masses of products via the grocery channel, however, because the latest unique code technology means easy scalability, low investment costs and high ROI.

Hive recently checked how many promotions there were on FMCG products in two major supermarket chains in the UK; we identified 60 different on-pack promotions during a one-week period, with 39 of them (65% of the total) carrying unique codes on pack.

However, many marketers right now are failing to exploit codes properly, as they are only deploying them as part of specific on-pack promotions and hence printing them only on a limited number of products. Only two of the 60 promotions we identified in our ‘quick and dirty’ survey were using unique codes printed on every pack they produced; the rest were using them on specially printed promotional packs.

If marketers print unique identifying codes on pack as a standard part of the production process, then they are no longer restricted to using them in for short-term, tactical pack-led promotions. They become a mechanic that can be turned on and off, effectively at the touch of a switch, allowing marketers to react to events today, not just in a few months’ time when brand plans have been confirmed It’s not just marketers that will find them invaluable, however; they can also be used to check that the right product is going to the right areas and individual stores, to combat counterfeiting and also to facilitate product recalls.

With promotional codes on every pack, marketers can run a huge range of different promotions without the lead time involved in printing promotional packs and across the whole of their product range – or they could even run two promotions simultaneously, split by retailer, geographic location or target consumer demographic.

Furthermore, with codes already on pack, marketers can use any channel or combination of channels they prefer to carry marketing messaging which explains the offer and how consumers can claim their incentives and rewards by activating these codes. There is the additional benefit that promotions can include packs which may already be scattered around consumers’ homes, on products they have already bought and that are in their kitchens, bathroom cabinets and elsewhere.

While at the moment ID codes tend to be used as a way to verify product purchase as part of a classic on-pack promotion, once they appear on packaging as a matter of course brand marketers will have a completely free hand when it comes to utilising them. They can use on-pack, Direct Marketing, digital, mobile, broadcast, press and Out Of Home (OOH) instead, and in any combination. Of course, they can also use on pack, if they wish.

Dairy products brand Anchor, for example, has been working with Hive and its marketing agencies, using unique codes on its packs to support and reinvigorate its Customer Relationship Marketing (CRM) programme, using only direct marketing as the communications channel.

Anchor created a whole range of direct mail messages to achieve three main objectives:

- To link more of their campaigns to purchase, which can now be measured by codes entered.

- To drive consumer engagement more regularly and allow for frequency of engagement to be measured over time.

- To increase the active number of members participating in the program, as measured by the number of codes entered by different individuals over time.

A sophisticated database segmentation method was developed which used activity-based rules as a driver to determine which emails were sent to which consumers and when. Anchor’s marketers and its agencies could clearly define the customer base and their ‘lifestyle’ stages, in terms of their relationship with the CRM programme, and then create key phases for the programme, including Welcome, Activation, Development and Win-back.

This DM driven programme has delivered phenomenal results:

- 17% increase in new members entering two or more codes.

- Average code entry increased by 35%.

- 3% of users who have never entered a code before were incentivised to do so.

- 20% of lapsed members were re-engaged and became active again.

- additional sales value due to halo affect or incremental sales driven outside the CRM.

Anchor created a whole range of direct mail messages to achieve three main objectives:

- To increase the number of codes being redeemed.

- To shorten the time between entering the first code and the second code, to get consumers into the habit of entering their codes.

- To increase the number of active members on the platform so driving engagement levels.

We have also been working with the UK arm of Chilean company Concha y Toro, the biggest wine producer in Latin America and the fourth largest in the world. It regularly runs on-pack promotions, with branding and specific marketing messaging usually conveyed on neck collars (due to the lead time involved in labelling wines as well as lack of space on wine labels).

Concha y Toro UK ran a neck collar promotion in September 2015 for its Isla Negra brand. The #MyIslaNegra promotion offered consumers the chance to win one of 50 £3,000 cash prizes to spend on a dream holiday. This was a repeat of a promotion that had run the year before, but the 2015 campaign incorporated Hive codes for the first time, using them to provide proof of purchase and also as the entry mechanism for the prize draw.

To find out if they had won a prize, shoppers had to go to the promotional website myislanegra.co.uk, enter the neck-collar code and play a fun beach game.

The 2015 #MyIslaNegra promotion drove a 53% uplift in rate of sale year on year, which was twice the uplift that the previous year’s activity achieved without unique ID numbers.

Putting codes on pack as a matter of course removes a massive planning and logistical burden from the marketing team. If they use classic on-pack promotions (whether involving codes or not), then they are committing themselves to long lead times to get promotional details on pack, as well as to significant extra printing costs.

Furthermore, brands are at the mercy of retailers as to when their packs get put on shelf – marketers often have their campaigns disrupted by retailers deciding to delay when promotional packaging goes in store. In some cases, promotional packs for competitions have only gone on shelf after the entry deadline has passed, not only massively reducing the impact of the promotion but potentially causing problems for the brand owner with the authorities.

In the UK, the CAP Code (the rules which govern all marketing in the UK) demands that marketers have to publicise an end-date for promotions – and the industry regulator, the Advertising Standards Authority (ASA), has in the past investigated complaints where consumers have bought promotional packs in order to enter a competition and then discovered that the entry date has passed.

If codes are on every pack and promotions are activated ‘remotely’, through advertising, DM, online and mobile activity or via POS in-store, then marketers can avoid this issue and no longer have to worry about ‘expiry dates’ on promotional packs beyond which the products effectively become ‘dead weight’ in store. All the relevant – and required – information about a promotion can be delivered digitally or via other communications channels.

Some brands which have investigated using unique codes have baulked at the cost and complexity in the past. One major FMCG company which was exploring using unique codes as part of an existing loyalty programme that involved two billion packs a year was dissuaded from doing so because it was quoted a cost of coding which equated to 50% of total campaign cost.

The latest new technology, however, has significantly cut the costs of using unique codes. When United Biscuits (UB, now part of the Pladis group), the UK’s leading manufacturer of sweet and savoury biscuits, introduced Hive’s on-pack unique coding solution, it did so because costs were 80% lower than the ‘old tech’ solution they had been previously quoted. Production line speeds were completely unaffected, even though the codes were going onto over 1.5 billion packs.

Technology has now evolved to the point where CPG brands can put unique ID codes on all their packaging and link them to the Internet of Things easily, cost-effectively and without any appreciable impact on their production lines.

They can be using the data they gather from consumers registering and using codes to gauge the impact of their marketing virtually in real time, run split promotions and even switch messaging and incentives within hours, respond to peaks and troughs in demand by introducing new promotions and ad campaigns to drive purchase, test new product launches, see differences in sales in rival retailers…

The opportunities offered by using unique codes on pack are only limited by the marketers’ imagination.

Jonathan Jackson is CEO of marketing technology company Hive and was guest speaker for a webinar on ‘The Internet of Packaging’ organised by the Institute of Promotional Marketing on October 20th 2016. The webinar and presentation are available to download. Please contact the IPM team on contact@theipm.org.uk to request your link.